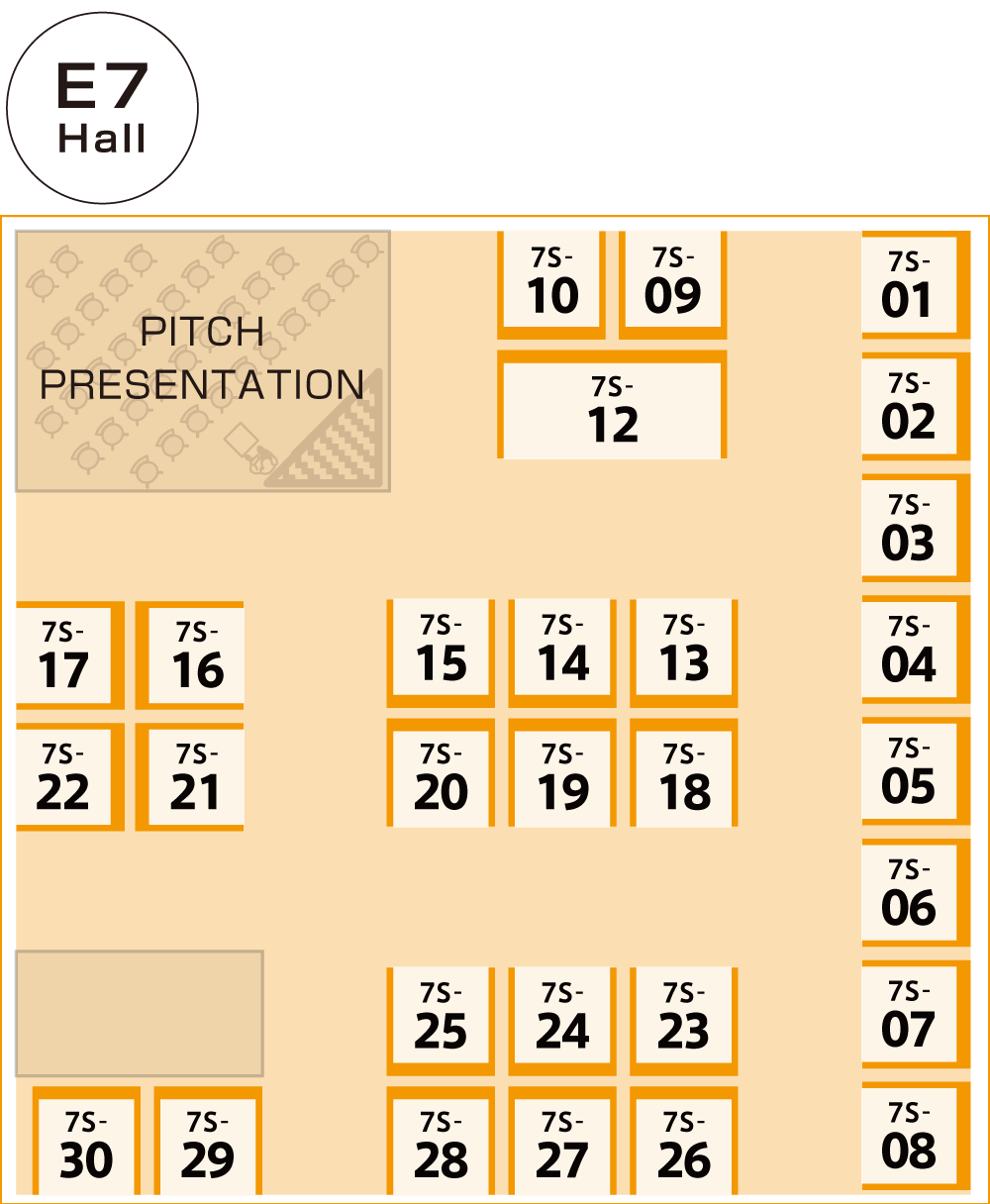

FOOMA JAPAN supports Food Startups to accelerate innovation in food manufacturing. 30 startup enterprises showcase new technology. The Startup Zone is where you can find new innovative ideas.

7S-01

HUTZPER INC.

7S-02

CANBRIGHT

7S-03

JTG CO., LTD.

7S-04

BALL WAVE INC.

7S-05

LIGHTBLUE TECHNOLOGY

7S-06

LOSSZERO CO., LTD.

7S-07

MMP CORPORATION

7S-08

TOKYO DYNAMICS CO., LTD.

7S-09

SMASHOKU, INC.

7S-10

ROBOTS TOWN CO., LTD.

7S-12

CLOSER, INC.

7S-13

HAPIKURO & CO.

7S-14

IOT MOBILE

7S-15

NPC CO., LTD.

7S-16

J BIO FOOD RECYCLE CORPORATION

7S-17

SMART HUNDRED CO., LTD.

7S-18

ASTRA FOOD PLAN CO., LTD.

7S-19

ROBOKARU INC.

7S-20

REGNIO

7S-21

QUINY, INC.

7S-22

ARK INC.

7S-23

ANAMORPHOSIS NETWORKS CO., LTD.

7S-24

FINGERVISION CO., LTD.

7S-25

GHELIA INC.

7S-26

SPICE CUBE INC.

7S-27

ICS-NET INC.

.png)

7S-28

SUZUYO SOLUTIONS CO., LTD.

7S-29

LOZI INC.

7S-30

FRIEND MICROBE INC.

| June 6 (Tue) | 10:30~10:50 | Creating a small sea on land to let the ocean recover. ARK INC. Creating a small sea on land to let the ocean recover. A startup manufacturer developing, manufacturing and selling a small and distributed closed recirculating aquaculture system (CRAS). Introducing ARK, a sustainable container-type land-based aquaculture system that can be deployed anywhere and by anyone. |

|

|---|---|---|---|

| 11:10~11:30 | Taking frozen food products to the next level with Smart Kaito . SMART HUNDRED CO., LTD. Fishery products are often frozen for storing and transporting over long periods. The products have to be defrosted in order to use them, and most are left out to defrost naturally. However, natural defrosting takes time and can cause issues like dripping, therefore, Smart Kaito technology utilizes 100MHz electromagnetic radiation to get round that problem. With Smart Kaito, you can take frozen food products to the next level with rapid, high-quality non-drip defrosting. The technology eliminates food loss and is kind to the environment. |

||

| 11:50~12:10 | The possibilities of DX that AI can bring to food factories and stores. LIGHTBLUE TECHNOLOGY Manufacturing sites have depended on the human eye for safety and quality control, operating efficiency and process checking. We will focus on the latest cases to explain how AI is being introduced and what role it plays on those production floors. We will also present no-code inhouse development tools for AI which enable high-speed and low-cost installation of AI systems. With the aid of demos, we will show how easily AI can be introduced today. If you haven’t taken steps towards DX because you don’t have a budget and don’t understand AI well enough, then this is a must-see. |

||

| 13:00~13:20 | Why automation isn’t progressing on the factory floor, as seen from a manufacturing engineer’s perspective. ROBOTS TOWN CO., LTD. A former food factory engineer talks about the future of food manufacturing and introduces FOOD TOWN, the first ever advice service dedicated to automation in the food industry. Why don’t younger generations want to work in the food industry? How can we create factories they want to work in? We present FOOD TOWN which was developed with a view to improving factory facilities. In cooperation with FOOMA JAPAN 2023, FOOD TOWN promotes automation for solving labor shortages in the food industry. |

||

| 13:40~14:00 | Recent AI developments in the food processing industry.

GHELIA INC. Learn about the latest industry trends with previous releases, research & development examples, and leading companies’ AI initiatives. Visual inspections, forecasting demand, optimization, etc. with AI. Agenda - Current state of AI in food processing - Latest initiatives in the industry - Examples of our initiatives - Conclusion |

||

| 14:20~14:40 | Utilizing Web services to speed up food product development. ICS-NET INC. Developing and releasing food products takes a long time. ShareShima has expanded its service to include summarizing and condensing information related to food development. Here we will explain how to take advantage of the service. |

||

| 15:00~15:20 | Contributing to SDGs through food recycling & bio-fuels generation J BIO FOOD RECYCLE CORPORATION Our business leverages the strengths of the JFE Engineering group which operates bio-fuels power generation facilities and deploys waste disposal technologies, and East Japan Railway group which tackles with food waste reuses, with our focus on initiatives to “convert food waste into electricity.” In this presentation, we will introduce the current state of food recycling, examples of how we are improving food recycling rates, and food recycling initiatives that contribute to SDGs, such as the provision of renewable energy and the recycling of fertilizers derived from food waste. |

||

| June 7 (Wed) | 10:30~10:50 | The AI production control service, RegnioFactory. REGNIO Introducing “Regnio Factory”, a production control automation service for food manufacturing that utilizes AI. Regnio Factory can provide services from production planning, materials control, production performance control, inventory control, and shipping control at an affordable cost. We will present its detailed functions and features, from automatic production planning to automatic ordering of materials, automatic issuance and entry of production instructions, automatic checking of expiration dates, and automatic issuance of shipping instructions. |

|

| 11:10~11:30 | Looking ahead to a zero-waste future. Creating new value from food loss.

LOSSZERO CO., LTD. With the spread of SDGs and the term “food loss,” consumers’ awareness of what constitutes “waste” has changed, leading to pro-active purchases. We use subscriptions and e-commerce to share your carefully-made food products with end-consumers, and upcycle them to new products to produce solutions that prevent brand damage. We will present specific examples of the use of out-of-specification products, surplus inventory, and unused materials. |

||

| 11:50~12:10 | Farming anywhere in the world.

SPICE CUBE INC. Even with a decline in food self-sufficiency due to decreasing and aging agricultural population, high unemployment among disabled people, the need for support during COVID lockdown restrictions, etc., LED lighting and cultivation technology can be used to simplify agricultural production. We believe that if we can spread this cultivation technology not only to companies but also to individuals, it will change society for the better. Since vegetables can be grown using only water and electricity, anyone can easily farm anywhere and produce high-quality vegetables that are “pesticide-free, safe and secure”. The equipment needed is about the size of a 1m2 bookcase, so it only needs to be placed, and its maintenance-free structure reduces agricultural labor (1 hour at a time per week), fitting in with your lifestyle. |

||

| 13:00~13:20 | It’s finally arrived! Daily lunch boxes served up by robots. FINGERVISION CO., LTD. The serving of bento boxes and side dishes, which are produced in many varieties and in small to medium quantities, is not easy to automate and continues to depend on the human touch. Its labor intensive nature has been seen as an issue for many years, so why is it so difficult to change? There are six obstacles to automation: (1) irregular shapes and individual differences, (2) wide variety and daily changes, (3) short takt time, (4) low labor cost unit price, (5) low production ratio for dedicated machines, and (6) short production time. In this pitch, we will demonstrate our strategic and technological approach to problems that are seemingly difficult to solve. |

||

| 13:40~14:00 | Reducing Hidden Food Loss with Superheated Steam processing. ASTRA FOOD PLAN CO., LTD. ASTRA FOOD PLAN is a food tech venture that develops and sells a “superheated steamer” (patent pending) that uses superheated steam technology. The “superheated steamer” has achieved high production efficiency and cost performance, so it is possible to upcycle food ingredients such as the core, skin, and calyx of vegetables, which could not previously be used effectively due to costs. We aim to solve the problem of food loss by selling “superheated steamer” to businesses that have issues with disposing of food waste, and at the same time develop new applications for food ingredients made with this equipment in cooperation with food manufacturers. |

||

| 14:20~14:40 | Connecting the food value chain with SmartBarcode. LOZI INC. SmartBarcode is a “Products Passport” solution that makes all barcodes smart and traceable from your smartphone. Recording the raw materials and processes used through to the end-product makes it possible to visualize the entire food value chain, such as how much was spent on the end-product, by integrating logistics information such as transportation routes and transportation quality. |

||

| June 8 (Thu) | 10:30~10:50 | An AI robotics spin-off venture from the University of Tsukuba and its challenges in supplementing the food factory labor force CLOSER, INC. This startup company from the University of Tsukuba has developed an AI system that automates food factories secondary packaging process (packaging, boxing, etc.). We will present a system that can handle a wide range of primary packaging and various pick-and-place tasks by AI image processing and robot control, and discuss examples of challenges towards its introduction in practice. |

|

| 11:10~11:30 | Reforming the workplace with ERP food manufacturing and production control systems. SUZUYO SOLUTIONS CO., LTD. Introducing an all-in-one ERP system for the food manufacturing industry. Food safety and security depends on the adoption of IT. The way to realize it is through unified database management, with a streamlined system from order receipt to shipping and delivery. We propose package software with the best proven record in the food manufacturing industry for its reliable, cost-effective, and short-term production control system. All kinds of food loss are thoroughly reduced through visualization and automation of the manufacturing process. You can improve profitability through real-time manufacturing cost management. |

||

| 11:50~12:10 | How to success a process automation project without having a production engineering department ROBOKARU INC. Automation with collaborative robots that work alongside people is currently a hot topic. However, in the food industry, many companies do not have a production technology department dedicated to automation and efficiency. And we hear about problems where they can’t make good use of the robot they’ve purchased or that they aren’t able to introduce one as quickly as they’d like. We will explain, using a successful example, how best to further automation with collaborative robots in such companies. |

||

| 13:00~13:20 | Measuring food product odors with Sylph. BALL WAVE INC. Ballwave Inc., a startup from Tohoku University, has developed an ultra-compact gas chromatograph, Sylph, in cooperation with JAXA. It uses a ball SAW sensor characterized by compactness, high speed, and high sensitivity. Since the gas chromatograph can isolate and analyze odor components, it can be applied to control food freshness, fermentation in brewed products such as alcohol, and the quality of beverages such as Japanese green tea and coffee. In our presentation, we will discuss the visualization of odors while showing various data on the theory. |

||

| 13:40~14:00 | Better accuracy than sensors! Visual inspection AI for food! HUTZPER INC. We present the fast, easy, and skillful AI for visual inspections. By replacing human inspection work with low-cost AI that realizes an early return on investment, we can solve labor shortages, stabilize quality, and improve operational efficiency. It can also be introduced easily as an integrated service system from environment creation to AI operation by optical engineers and AI engineers. We also own advanced technology dedicated to factories, to support the creation of non-defect producing factories through our alignment with auxiliary equipment such as exclusion mechanisms. |

||

| 14:20~14:40 | Revolutionizing food manufacturing site operations with Tsukurude SaaS. CANBRIGHT We will discuss the introduction and selection of systems to reform working practice at small to medium-sized companies’ food manufacturing sites. At the same time, we will introduce examples of Tsukurude SaaS being implemented successfully with our support. |

||

| June 9 (Fri) | 10:30~10:50 | Food labelling and standards DX, introduced by over 2,500 companies. SMASHOKU, INC. My first impressions of food labelling was that it was such a hassle! Failure to create labelling compliant with over 1,200 pages of relevant laws and regulations means the company can be penalized and its reputation in the food industry tarnished. Control of standards is difficult to follow to the letter. The key to this problem is automation (DX)! Many companies have managed to save time and labor by 80% (some by 90%) or more. |

|

| 11:10~11:30 | Leaving a world for our grandkids and their grandkids! A million-tonne waste reduction plant! MMP CORPORATION Key MMP technologies: ❶ The refining and recycling rate of waste cooking oil is 91%, more than twice that of the industry average. ➋ The world's first high-performance biodegradable lubricating oil to decarbonize construction sites and forest thinning sites. ❸ Decarbonization by using recycled fuels as substituents as fossil fuel additives and with improved fuel efficiency. We took on the challenge of on-site operation for restaurants, etc. with full plant automation, and realized high-purity regeneration in addition to elimination of logistics and stabilizing supply. We also declared the fuel for power generation at our sites to be carbon neutral. To promote its introduction, we offer a subscription charging method based on liters of refined volume without capital expenditure. The target is to reduce CO2 emissions by 1 million tons and realize a power microgrid, thereby contributing to regional supply in the event of a disaster. |

||

| 11:50~12:10 | Changing conventional manufacturing and sanitary control practices with DX! HAPIKURO & CO. At food manufacturing sites, various records are created for manufacturing and hygiene management, but most sites have not been able to transition away from using paper forms and documents, thereby slowing the progress of DX. In addition to going paperless and digitalization, we will introduce you to DX solutions, which utilize IoT technology to automate and improve record-keeping, and leverage data to improve the level of manufacturing and hygiene control. |

||

| 13:00~13:20 | Ondotchi, a temperature control system costing 350 yen a month. IOT MOBLE Isn’t it time to end manual control of temperature? Ondotchi is a rental-type temperature control system that automatically measures the temperature inside fridges and freezers by means of a sensor, and notifies you by email and telephone about any abnormalities. In our pitch, we will discuss Ondotchi’s features and functions and let you hear the candid views of companies that have adopted it. |

||

| 13:40~14:00 | Automation, low cost, improving the environment with technology that reduces petroleum waste. FRIEND MICROBE INC. A high-performance oil-degrading microbe developed in a national project at Nagoya University. We will present the business background of a startup from Nagoya University that has developed microbial technology to reduce industrial waste containing fats and oils. Currently, processing oil waste takes manpower, expense, and releases fumes. In this project, microorganisms are used in areas such as food plant wastewater, restaurant wastewater, and food waste treatment for automation, cost reduction, and environmental improvement. |

||

| 14:20~14:40 | A beer Meister robot tailored to your preferences. QUINY, INC. This year, we will exhibit a robot that serves beer like a professional beer Meister. We succeeded not only mimicking the Meister’s behavior, but also in creating the difference in taste like a real Meister. This time, we will explain the background of its development and detailed specifications, and present various scenarios in which we can envisage its usage. |

||