Fermentation and ripening monitoring system

Product Catalogs Available

FOOMA JAPAN Debut

New Products

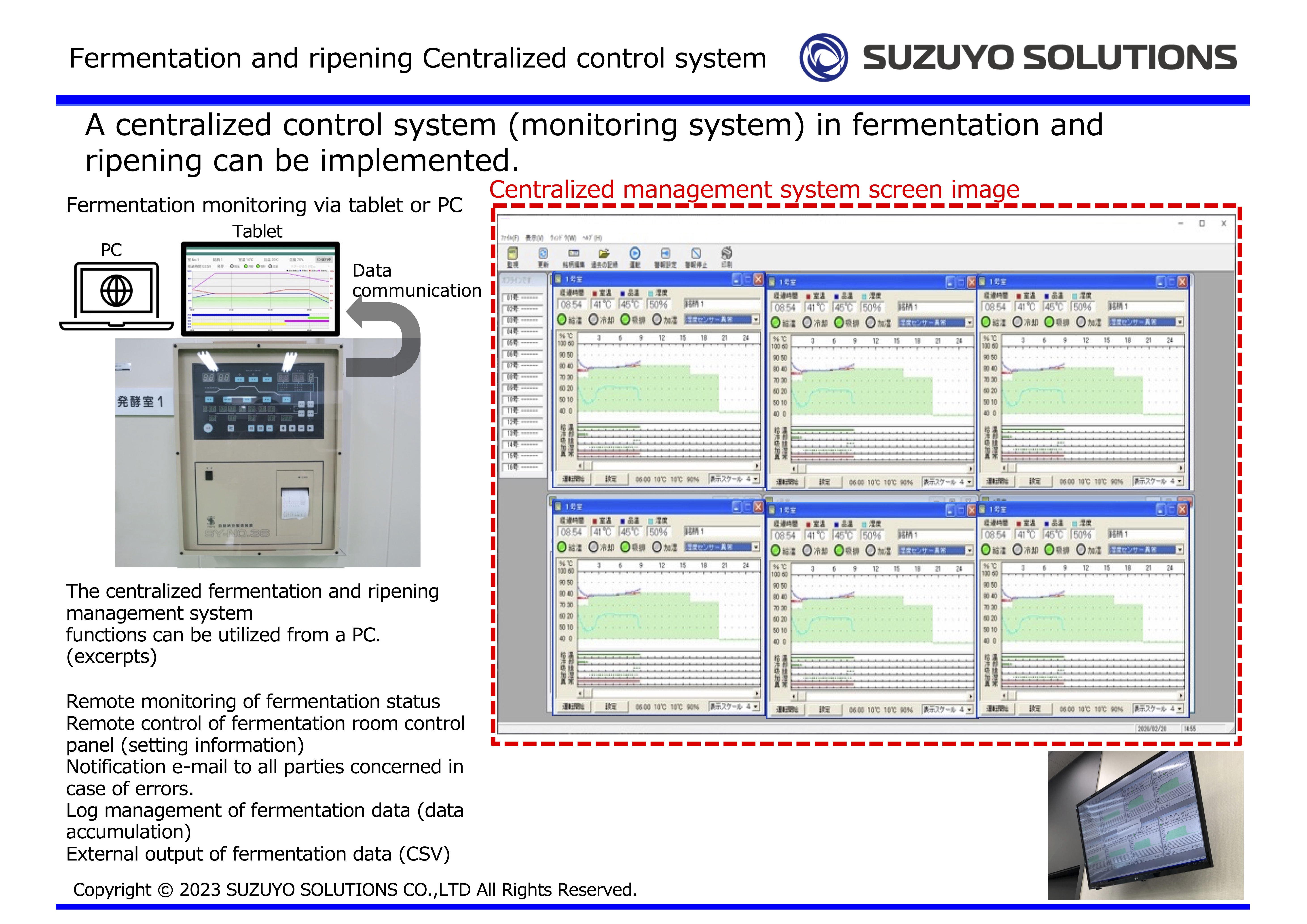

A centralized management system is now available that allows for integrated management of fermentation rooms via PC.

Monitoring and monitoring the operation status with a forecast/actual graph that allows you to check the fermentation status at a glance.

Reduction of workload by centralized manageme

- Food Manufacturing, Processing, and Preparation ◎ Meats and Seafood:Ripening chambers

- Food Manufacturing, Processing, and Preparation ◎ Tofu:Natto processing equipment

- Food Manufacturing, Processing, and Preparation ◎ Fermented and Distilled Products:Equipment for making koji (malted rice)、Fermenters

- Engineering:Instrumentation and control systems、Traceability systems

- Robots, IT, IoT, and Food Tech:Software systems for food-processing plants、Sensors、Networking equipment and software

- Food Manufacturing, Processing, and Preparation ◎ Beverages and Dairy Products:Curing chambers

Overview of Products, Technologies, and Services

The status of fermentation and ripening can be easily checked.

The PC can be used to check the status at a glance, facilitating management of multiple rooms and reducing the workload of the person in charge.

Since past fermentation data is stored in the PC, there is no need to keep paper records.

When an error occurs in a fermentation room, an e-mail notification can be sent to a pre-set e-mail address.

Product Features

| Feature 1 | The room temperature, product temperature, and humidity of fermentation and ripening are displayed in a list, allowing the user to check the fermentation status at a glance. In addition, detailed information on each room is displayed graphically in the room window, and detailed monitoring is possible by tracing the difference between planned and actual results and by monitoring equipment operation. |

|---|---|

| Feature 2 | Individual data for each room can be freely set from a remote location using a personal computer. In addition, centralized management and remote control of start/stop operation, setting changes, etc. for each room can be performed from a PC. |

| Feature 3 | Automatic storage of fermentation data allows easy reference to past fermentation records. In addition, past records can be printed or exported to CSV for secondary processing of fermentation data for analysis and traceability. |